Plastic Optical Fiber (POF) is an optical fiber that uses plastic as the transmission medium. It is widely used in communications, industrial control, automotive electronics, medical equipment and other fields. Due to differences in process difficulty, materials and quality, various factors lead to different prices. Senwo Technology analyzes the factors that lead to price differences from multiple dimensions to let you know whether the money is worth spending.

Senwo Technology explains in detail how much plastic optical fiber costs per meter

I. Process and materials

(1) Raw material selection

Basic material: PMMA (polymethyl methacrylate): ordinary grade PMMA has a lower cost), but poor light transmittance and durability;

High-purity PMMA: After adding anti-aging and high-temperature resistant additives, the cost increases by 30%-50%, but the performance is better

Coating and protective layer:

Ordinary PVC outer layer: low cost;

Flame retardant or waterproof coating: cost increases by 20%-30%

(2) Manufacturing accuracy

Fiber core diameter:

Ordinary POF fiber core is 1mm, low cost

Precision fiber core (ultra-fine or thicker) requires more precise machines, and the cost is 20%-30% higher

End face processing:

Laser polished end face: low signal loss, cost is 50% higher than mechanical polishing

II. Differences in quality and performance parameters

Fiber bundle

(1) Transmission performance

Attenuation coefficient:

Ordinary POF: Attenuation coefficient is about 200~300 dB/km, low price

High-performance POF: Attenuation coefficient is 150dB/km-180dB/km, cost increases by 30%-50%

Bandwidth and speed:

Ordinary POF: Transmission rate ≤100 Mbps, low price;

High-speed POF: above 1Gbps: need to optimize materials and structure, cost doubles

(2) Extreme environment

Temperature tolerance:

Ordinary POF: Working temperature -20℃~70℃, low cost;

Special POF (-40℃100℃): Special materials are required, price increases by 20%-40%

Bending resistance:

Ordinary POF: Minimum bending radius ≥15cm;

Ultra-flexible POF: can be bent repeatedly 6-10 times, cost increases by 30%-50%

(3) Certification standards

International certification:

Comply with ISO and IEC standards: additional testing fees are required, cost increases by 10%-20%;

Industry certification: such as automotive-grade AEC-Q100 and medical-grade FDA certification: cost may double.

3. Differences in application scenarios and needs

(1) Industry applications

Consumer market:

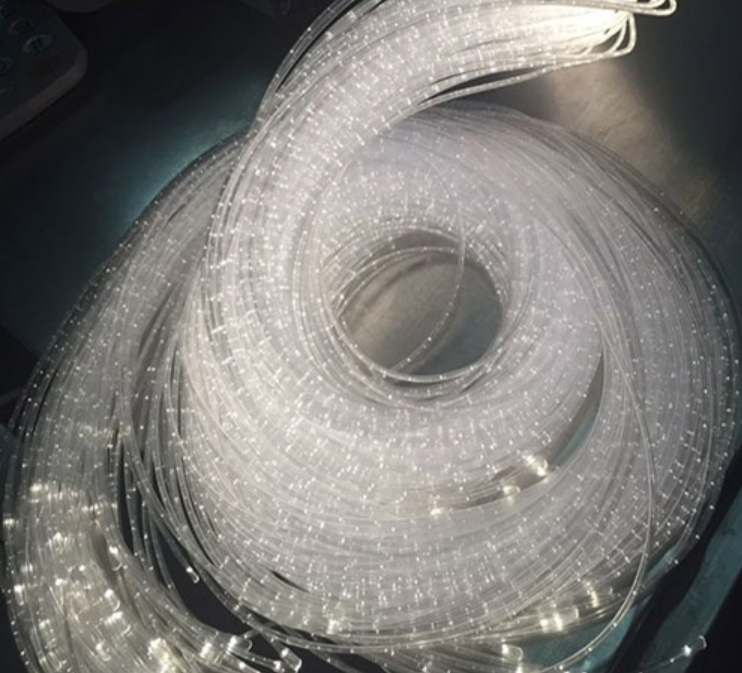

Home entertainment, LED decorative lights: low price

Audio transmission: such as audio jumpers, the cost is 10%-20% higher

Industrial market:

Automotive wiring harnesses, industrial sensors: relatively low price

High temperature environment (such as industrial furnace): special POF has high cost

High-end field:

Medical endoscopes, aerospace: customized POF is very expensive

(2) Bulk purchase

Small batches have higher costs, while large batches have lower costs

4. Market and brand factors

(1) Brand premium

International brands:

Fujikura of Japan, Lumerical of the United States: mature technology, prices are 30%~50% higher than domestic ones;

For example: ordinary POF is about 1 yuan/meter for domestic ones, and can reach 1. The price per meter is between 2 yuan and 4 yuan.

Domestic manufacturers: Changfei, Senwo Technology, high cost performance, suitable for mid- and low-end needs

(2) Regional differences

Imported optical fiber: logistics and tariff costs push up prices (e.g. European products may be more than 20% more expensive);

Domestic optical fiber: low cost but quality varies

5. Other additional costs

Plastic optical fiber dotting

Connectors and accessories:

Bare optical fiber: basic price;

With connectors (such as SC/FC interfaces) or special interfaces (such as TOSLINK), there will be additional costs

After-sales service:

Long-term warranty or technical support: may be implied in the price (such as an increase of 5%~10%).

Purchase suggestions

Clear requirements:

Select the grade according to the transmission distance, rate, and environmental conditions (e.g. industrial grade requires high temperature resistance).

Compare parameters:

Pay attention to core indicators such as attenuation coefficient, bandwidth, and temperature range.

Whether it is a manufacturer and whether it is qualified for certification

Confirm whether it provides quality certification and after-sales service.

Summary

The core of the price difference of plastic optical fiber lies in performance requirements and manufacturing complexity. In areas such as medical and industrial that require high accuracy and high safety, the cost is higher. When using products, customers need to consider the trade-off between quality and price. Do not buy beyond your ability to bear.

CopyRight © Senwo technology . All Rights Reserved TEL:+86-717-4828268 网站地图